Technology

Shaping the Future with Innovation

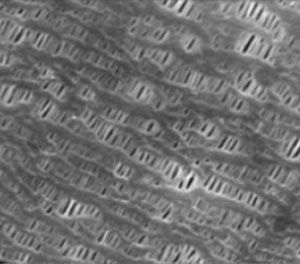

High Gap Diaphragm

GREPOW

Diaphragm with a dense porous structure, which allows it to achieve a more uniform pore distribution which in turn can reduce internal resistance and improve discharge performance of our batteries.

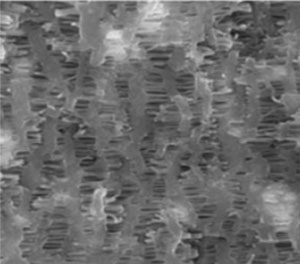

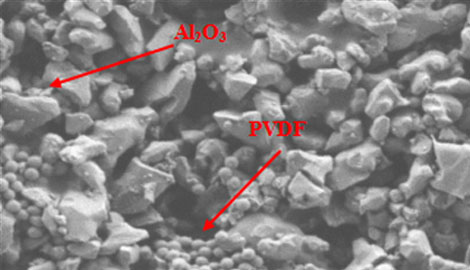

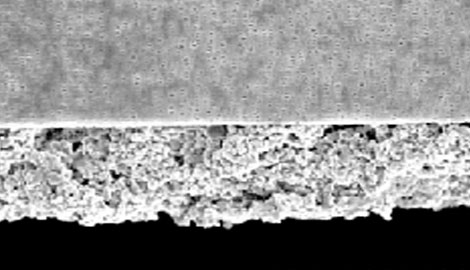

Ceramic Diaphragm

The surface-coated nano-ceramic battery separator has the advantages of high temperature resistance, high voltage resistance, high puncture and high liquid absorption, which can greatly improve the heat shrinkage of the diaphragm and improve the safety and reliability of the battery.

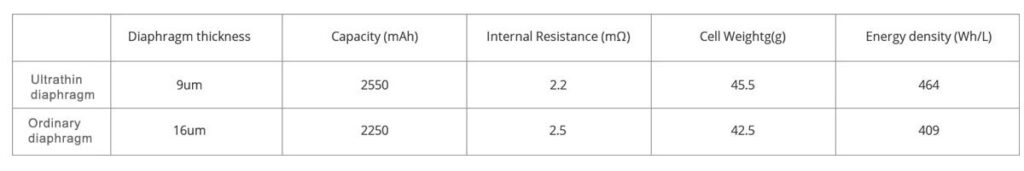

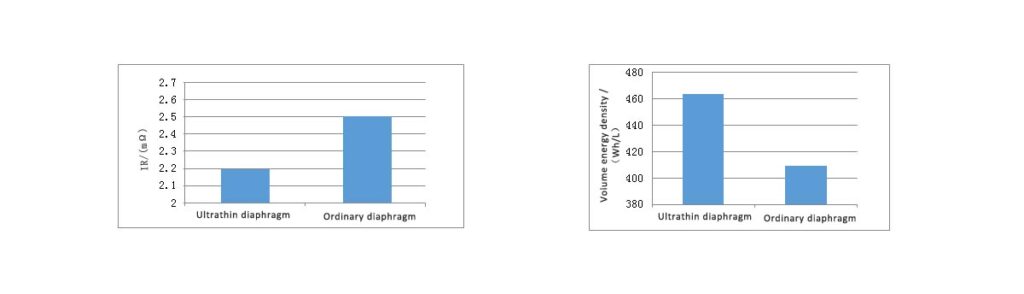

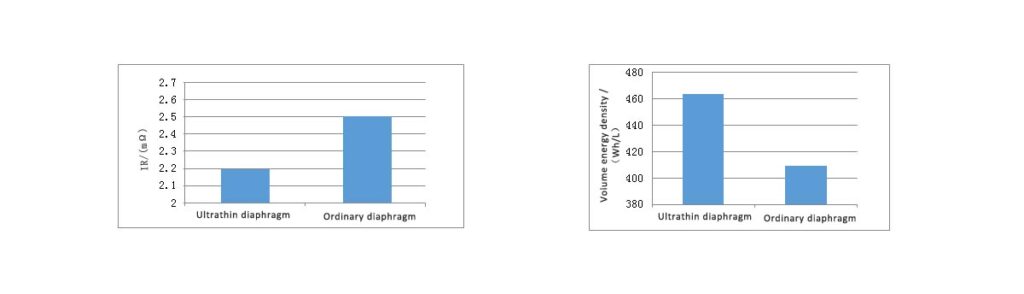

Ultrathin Diaphragm

The 9um diaphragm reduces the internal resistance of the battery and increases the volumetric energy density of the batteryBattery model:GRP574285-S

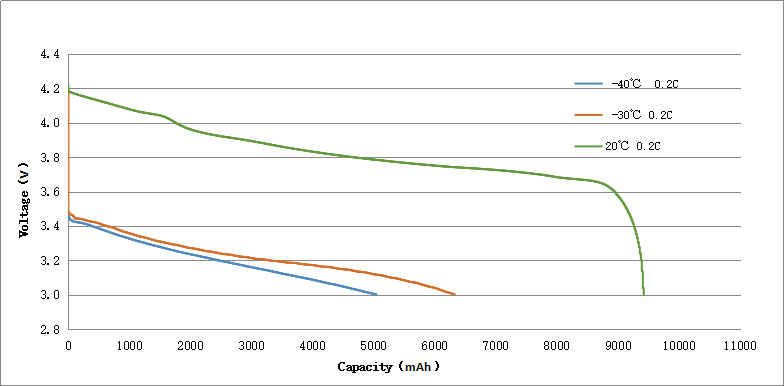

Low Temperature Electrolyte

Comparison of different temperature discharge curves of low temperature batteries.

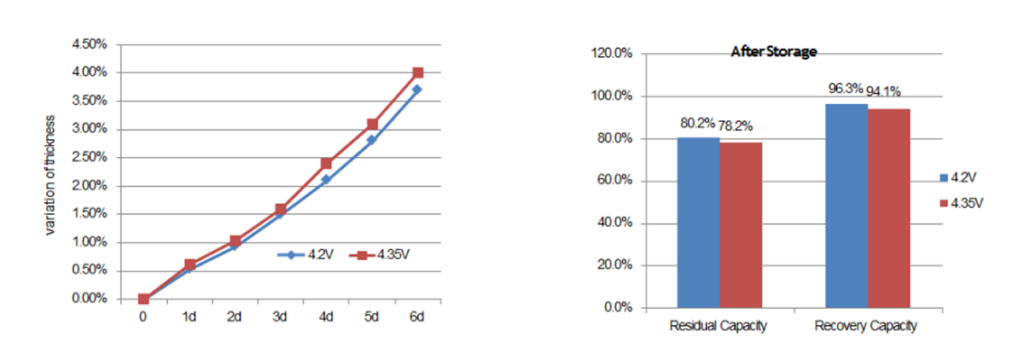

High Temperature Electrolyte Drone Battery

The cells were storaged at 70 ℃ for 7 days, variation of thickness <5%, recovery capacity >90%.

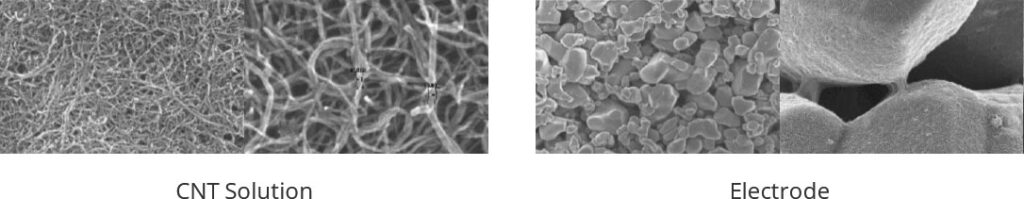

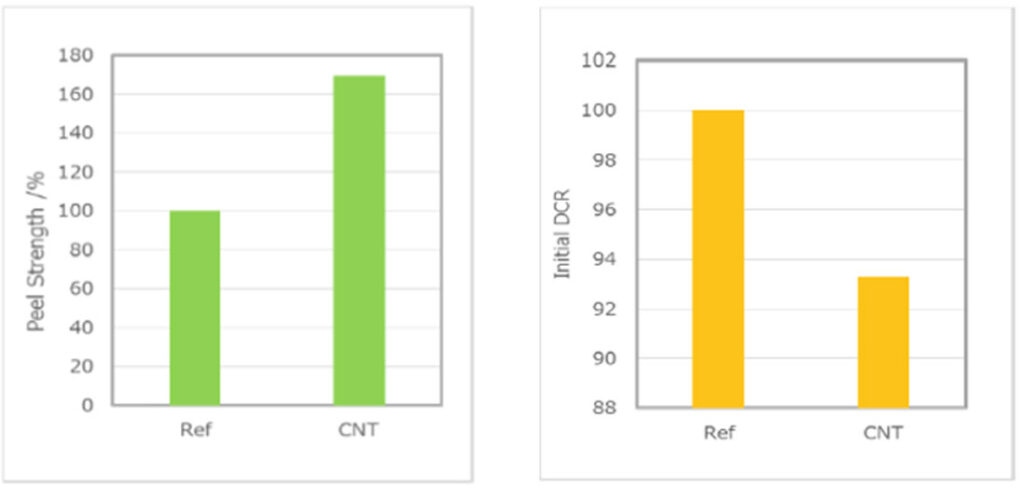

Bundle CNT(Carbon Nano Tube)

There is few agglomerate in CNT Solution.

In Electrode, CNT is well distributed on the surface of active materials.